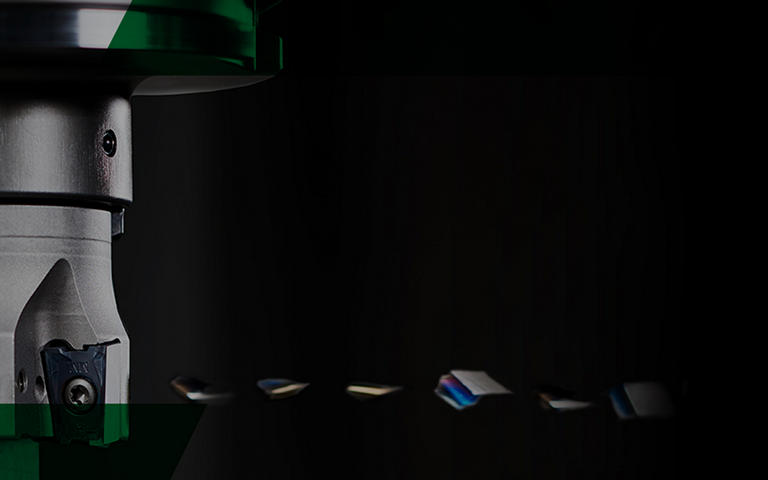

4 режущие кромки на пластине, фреза для обработки прямоугольных уступов

VSM490™-15 — это фреза с двухсторонними пластинами с 4-мя режущими кромками для черновой и чистовой обработки прямоугольных уступов. Для фрезы разработаны 4 геометрии режущих пластин для того, чтобы с высокой эффективностью обрабатывать материалы различных групп (стали, нержавеющие стали, чугуны, титановые и алюминиевые сплавы) и получать лучшее в своём классе качество обработанных стенок при многопроходном фрезеровании.

VSM490-15 — это инструмент All-Star.

Закажите инструменты с отправкой в тот же день с All-Star! Узнать больше.