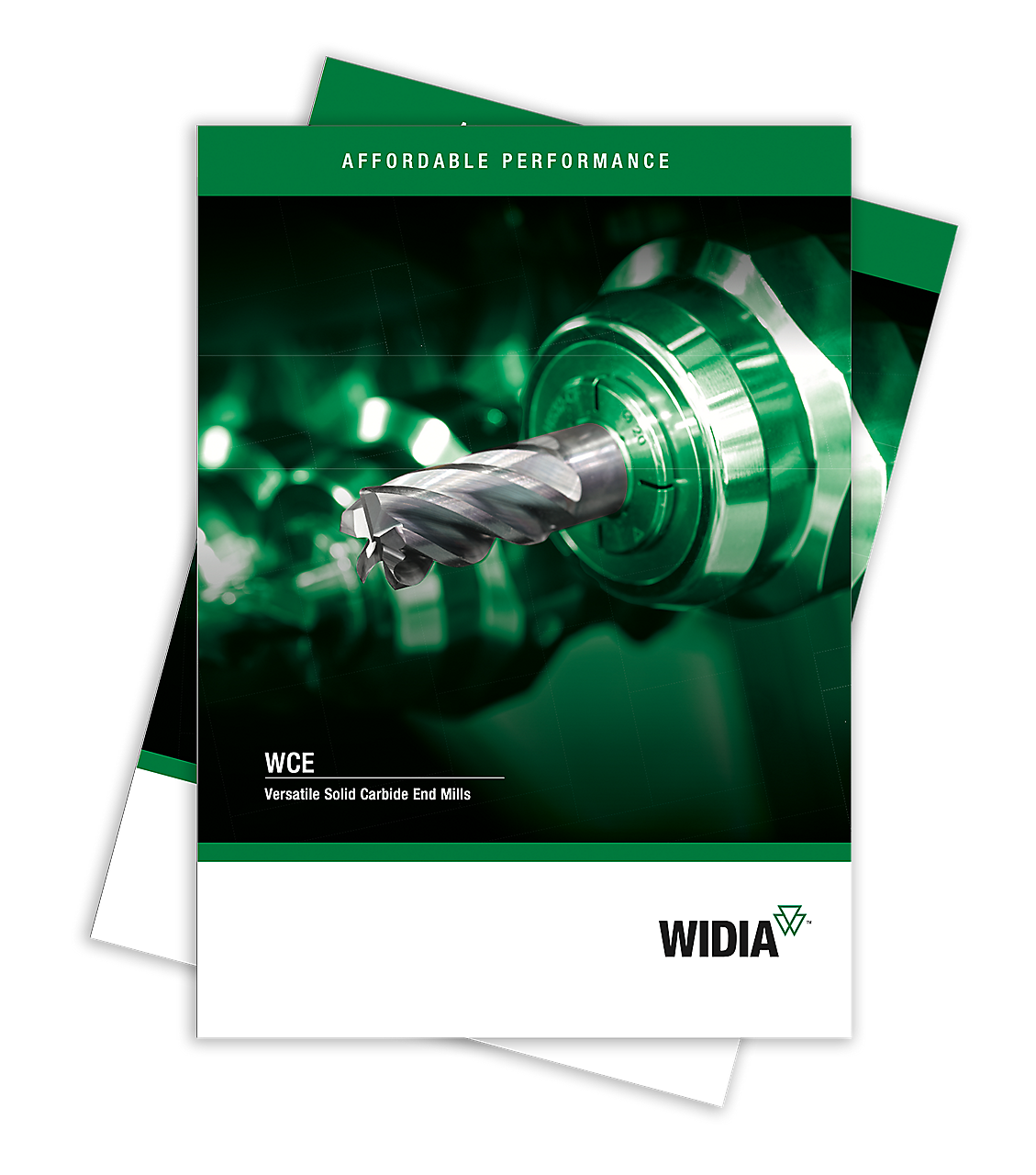

Affordable Performance

The WCE solid end milling platform packs a combination of high-performance and general-purpose features into one end mill family offered at an affordable price point in both 4- and 5-flute geometries. This small-to-medium shop staple is made to machine small batches.

The WCE4 4-flute geometry combines the asymmetrical index and variable helix features at an affordable price while ensuring material and application versatility, even on demanding operations like full slots and heavy cuts.

The WCE5 5-flute geometry combines the unequal index feature with an elevated 38-degree helix feature at an affordable price to be used primarily in Carbon Steel and Stainless-Steel shouldering/side milling applications.