Welcome

Please confirm your preferences

Update Preferences

Предложения по продукции

Product Family suggestions

WIDIA At Your Service

Customer Support

Find contact details to customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Уведомления

Отметить все как прочитанные - Change Password

- My Profile

- Logout

Позиции

успешно добавлено в корзину

View Cart

View Cart

WIDIA At Your Service

Customer Support

Find contact details to customer support centers around the globe.

Позиции

успешно добавлено в корзину

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Продукция

- /

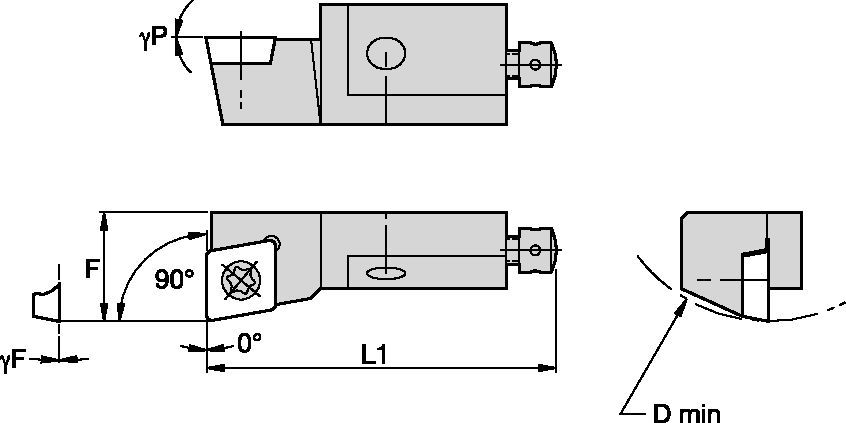

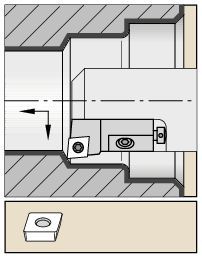

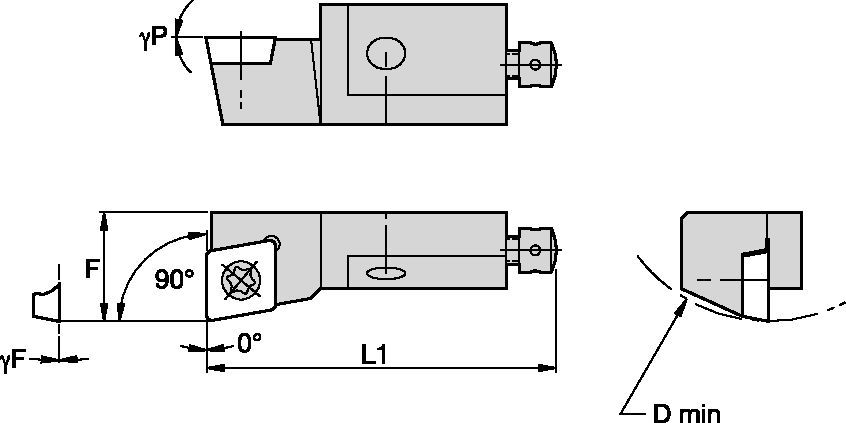

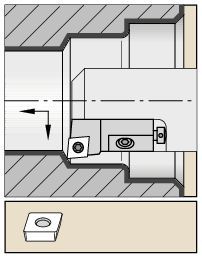

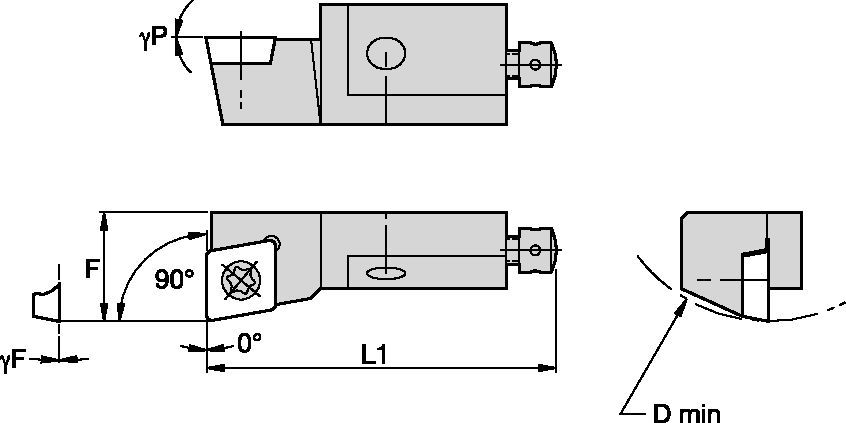

- SCFP 90°

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

SCFP 90°

Пластины KENLOC™