*に類似する製品:

M270トロイダル • TF

トロイダルインサート

製品番号6724710

ISO カタログ IDM270TF12R1ANSIカタログIDM270TF12R1

- K Cast Iron

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 6724710 |

| ISO カタログ ID | M270TF12R1 |

| ANSIカタログID | M270TF12R1 |

| Grade | WU10PM |

| Cutting Edges per Insert | 2 |

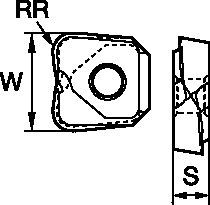

| [W] Cutting Width | 12 mm |

| [W] Cutting Width | 0.4724 in |

| [S] Insert Thickness | 3.18 mm |

| [S] Insert Thickness | 0.1252 in |

| [RR] Corner Radius | 1 mm |

| [RR] Corner Radius | 0.039 in |

ワーク材料

- Cast Iron

- Hardened Materials

特徴と利点

- 仕上げ加工および準仕上げ加工のアプリケーション向け精密インサート。

- バックドラフト設計で、振動を最低限に抑え、表面仕上げを向上。

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

送り量

推奨フィード量の開始値[mm]

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| TF | 0,12 | 0,37 | 0,62 | 0,09 | 0,26 | 0,43 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | TF |

| 軽切削加工 | 汎用 | 重切削加工 |

Recommended Starting Feeds [IPT]

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| TF | .005 | .014 | .024 | .003 | .010 | .017 | .002 | .007 | .012 | .002 | .006 | .011 | .002 | .006 | .010 | TF |

| 軽切削加工 | 汎用 | 重切削加工 |

速度

推奨切削速度の開始値[m/min]

| 被削材 グループ | TN2505 | TN6525 | TN6540 | WP35CM | WU10PM | |||||||||||

| P | 1 | 550 | 420 | 360 | 410 | 320 | 280 | 360 | 280 | 240 | 455 | 395 | 370 | – | – | – |

| 2 | 320 | 240 | 205 | 320 | 250 | 215 | 250 | 190 | 170 | 280 | 255 | 230 | – | – | – | |

| 3 | 320 | 240 | 205 | 280 | 215 | 185 | 215 | 170 | 140 | 255 | 230 | 205 | – | – | – | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | 190 | 175 | 160 | – | – | – | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | 260 | 230 | 210 | – | – | – | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | 160 | 135 | 110 | – | – | – | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | 205 | 185 | 155 | – | – | – |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | 185 | 160 | 140 | – | – | – | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | 145 | 130 | 115 | – | – | – | |

| K | 1 | 400 | 300 | 250 | 275 | 245 | 220 | 220 | 205 | 180 | 295 | 265 | 240 | 295 | 265 | 240 |

| 2 | 540 | 365 | 280 | 215 | 190 | 180 | 175 | 155 | 140 | 235 | 210 | 190 | 230 | 205 | 190 | |

| 3 | 310 | 190 | 155 | 180 | 160 | 145 | 155 | 145 | 125 | 195 | 175 | 160 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | 66 | 50 | 33 | – | – | – | |

| H | 1 | 175 | 140 | 95 | – | – | – | – | – | – | – | – | – | 160 | 130 | 90 |

| 2 | 175 | 140 | 95 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 140 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| 被削材 グループ | TN2505 | TN2510 | TN2525 | |||||||

| P | 1 | 1810 | 1380 | 1180 | 2165 | 1910 | 1770 | 1810 | 1380 | 1180 |

| 2 | 1045 | 785 | 670 | 1340 | 1220 | 1080 | 1045 | 785 | 670 | |

| 3 | 1045 | 785 | 670 | 1220 | 1080 | 1000 | 1045 | 785 | 670 | |

| 4 | – | – | – | 905 | 845 | 750 | – | – | – | |

| 5 | – | – | – | 1080 | 985 | 905 | – | – | – | |

| 6 | – | – | – | 750 | 670 | 570 | – | – | – | |

| M | 1 | – | – | – | 890 | 785 | 690 | – | – | – |

| 2 | – | – | – | 805 | 690 | 630 | – | – | – | |

| 3 | – | – | – | 630 | 570 | 490 | – | – | – | |

| K | 1 | 1320 | 985 | 830 | 1380 | 1180 | 985 | – | – | – |

| 2 | 1770 | 1200 | 925 | 1180 | 985 | 830 | – | – | – | |

| 3 | 1025 | 630 | 510 | 985 | 830 | 650 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | 570 | 450 | 310 | 475 | 360 | 230 | 430 | 295 | 200 |

| 2 | 570 | 450 | 310 | 475 | 360 | 230 | 430 | 295 | 200 | |

| 3 | 450 | 370 | 260 | 380 | 260 | 150 | – | – | – | |

インサート選択

| 軽切削加工 | 汎用 | 重切削加工 | ||||

| 被削材 グループ | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1–P2 | TF | WU10PM | TF | WU10PM | TF | WU10PM |

| P3–P4 | TF | WU10PM | TF | WU10PM | TF | WU10PM |

| P5–P6 | TF | WU10PM | TF | WU10PM | – | – |

| M1–M2 | TF | WU10PM | – | – | – | – |

| M3 | TF | WU10PM | – | – | – | – |

| K1–K2 | TF | WU10PM | TF | WU10PM | – | – |

| K3 | TF | WU10PM | TF | WU10PM | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | TF | WU10PM | – | – | – | – |

| S3 | TF | WU10PM | – | – | – | – |

| S4 | TF | WU10PM | – | – | – | – |

| H1 | TF | TN2505 | TF | WU10PM | – | – |

| 軽切削加工 | 汎用 | 重切削加工 | ||||

| 被削材 グループ | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1–P2 | TF | TN2505 | – | – | – | – |

| P3–P4 | TF | TN2505 | – | – | – | – |

| P5–P6 | TF | TN2505 | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | TF | TN2505 | – | – | – | – |

| K3 | TF | TN2505 | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | TF | TN2505 | TF | TN2505 | – | – |

I have read and accepted the Terms & Conditions of use