プロファイル加工用小径穴ボーリングバー

-

P Steel (24)

-

P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (24)

-

P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (24)

-

P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS (24)

-

P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS (24)

-

P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS (24)

-

P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS (24)

-

P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS (24)

-

-

M Stainless Steel (24)

-

M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS (24)

-

M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS (24)

-

M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS (24)

-

-

K Cast Iron (24)

-

K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS (24)

-

K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS (24)

-

K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS (24)

-

-

N Non-Ferrous Materials (24)

-

N1Wrought Aluminum (24)

-

N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2% (24)

-

N3High-Silicon Aluminum Alloys Si >12.2% (24)

-

-

US (5)

-

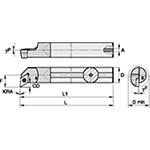

Back Boring (25)

-

Multiple Direction Cutting (27)

-

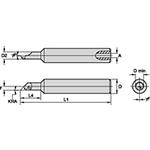

TRN Boring (27)

-

67.5 (5)

-

90.0 (6)

-

92.0 (2)

-

95.0 (14)

-

2.0 (24)

-

4.0 in (10)

-

4.5 in (2)

-

5.0 in (2)

-

6.0 in (9)

-

8.0 in (2)

-

10.0 in (1)

-

101.601 mm (10)

-

114.301 mm (2)

-

127.0 mm (2)

-

152.4 mm (9)

-

203.201 mm (2)

-

254.0 mm (1)

-

0.007 in (24)

-

0.015 in (24)

-

0.176 mm (24)

-

0.375 mm (24)

-

CG5 (24)

-

CG6 (24)

-

CM1 (24)

-

L (5)

-

R (22)

-

N (24)

-

4.275 mm (1)

-

5.601 mm (7)

-

6.0 mm (1)

-

6.375 mm (4)

-

6.601 mm (2)

-

7.0 mm (1)

-

7.926 mm (4)

-

8.6 mm (2)

-

9.5 mm (4)

-

11.101 mm (1)

-

0.168 in (1)

-

0.221 in (7)

-

0.237 in (1)

-

0.251 in (4)

-

0.26 in (2)

-

0.276 in (1)

-

0.312 in (4)

-

0.339 in (2)

-

0.374 in (4)

-

0.437 in (1)

-

8.6 mm (1)

-

9.15 mm (7)

-

10.15 mm (2)

-

10.75 mm (4)

-

11.375 mm (1)

-

13.076 mm (4)

-

13.726 mm (2)

-

15.875 mm (1)

-

16.0 mm (2)

-

16.25 mm (2)

-

19.425 mm (1)

-

0.339 in (1)

-

0.36 in (7)

-

0.4 in (2)

-

0.423 in (4)

-

0.448 in (1)

-

0.515 in (4)

-

0.54 in (2)

-

0.625 in (1)

-

0.63 in (2)

-

0.64 in (2)

-

0.765 in (1)

-

B (13)

-

E (12)

-

S (2)

-

NEGATIVE-ZERO (1)

-

NEUTRAL (ZERO) (26)

-

0.9 in (2)

-

1.0 in (5)

-

1.25 in (2)

-

1.417 in (1)

-

1.498 in (1)

-

1.499 in (1)

-

1.5 in (5)

-

1.875 in (2)

-

1.891 in (1)

-

2.0 in (2)

-

2.249 in (2)

-

3.0 in (2)

-

3.749 in (1)

-

22.85 mm (2)

-

25.401 mm (5)

-

31.75 mm (2)

-

36.0 mm (1)

-

38.051 mm (1)

-

38.075 mm (1)

-

38.1 mm (5)

-

47.625 mm (2)

-

48.0 mm (1)

-

50.801 mm (2)

-

57.125 mm (2)

-

76.2 mm (2)

-

95.226 mm (1)

-

C (12)

-

S (13)

-

S (22)

-

0.09 in (3)

-

0.091 in (6)

-

0.092 in (1)

-

0.098 in (1)

-

0.116 in (1)

-

0.12 in (6)

-

0.121 in (3)

-

0.13 in (2)

-

0.146 in (1)

-

0.147 in (1)

-

2.275 mm (3)

-

2.301 mm (6)

-

2.325 mm (1)

-

2.5 mm (1)

-

2.95 mm (1)

-

3.026 mm (2)

-

3.051 mm (4)

-

3.075 mm (3)

-

3.301 mm (2)

-

3.7 mm (1)

-

3.725 mm (1)

-

H W (24)

-

6.0 mm (1)

-

6.351 mm (3)

-

7.926 mm (2)

-

8.0 mm (1)

-

9.525 mm (3)

-

12.0 mm (2)

-

12.701 mm (7)

-

15.875 mm (6)

-

19.05 mm (2)

-

0.237 in (1)

-

0.25 in (3)

-

0.312 in (2)

-

0.315 in (1)

-

0.375 in (3)

-

0.473 in (2)

-

0.5 in (7)

-

0.625 in (6)

-

0.75 in (2)