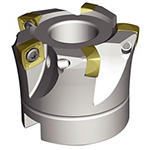

VXF™-09 Series - Tool Bodies

Filtry

Filtry

Zobrazit filtry v

MetrickéPalcové

Workpiece Material

Workpiece Material

- P Steel (28)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(28)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(28)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(28)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(28)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(28)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(28)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(28)

- M Stainless Steel (28)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(28)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(28)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(28)

- K Cast Iron (28)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(28)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(28)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(28)

- N Non-Ferrous Materials (28)

- N1Wrought Aluminum (28)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(28)

- N3High-Silicon Aluminum Alloys Si >12.2%(28)

- S High-Temp Alloys (28)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(28)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(28)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(28)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(28)

- H Hardened Materials (28)

- H1Hardened Materials 44-48 HRC(28)

Select All Star

- CN (1)

- DE (1)

- SG (1)

Applications

Applications

Face Milling (28)

Pocket (28)

Pocket Helical (28)

Pocket Milling (1)

Pocket Plunge Milling (28)

Profile Milling (28)

Ramping (28)

Shoulder Milling (1)

Shoulder Roughing (28)

Shoulder Square End (28)

Slot Milling (1)

Slot Square End (28)

Cutting Diameter

Cutting Diameter

- 0.4462 in(4)

- 0.4618 in(3)

- 0.7106 in(3)

- 0.7204 in(5)

- 0.8381 in(1)

- 0.9599 in(2)

- 1.0346 in(2)

- 1.1132 in(2)

- 1.4266 in(2)

- 1.4581 in(2)

- 1.5053 in(1)

- 1.9382 in(1)

komu

Cutting Diameter

Cutting Diameter

- 11.333 mm(4)

- 11.73 mm(3)

- 18.048 mm(3)

- 18.297 mm(5)

- 21.289 mm(1)

- 24.382 mm(2)

- 26.279 mm(2)

- 28.276 mm(2)

- 34.235 mm(1)

- 36.235 mm(1)

- 37.035 mm(2)

- 38.234 mm(1)

- 49.23 mm(1)

komu

Maximum Cutting Diameter

Maximum Cutting Diameter

- 25.0 mm(4)

- 25.4 mm(3)

- 31.75 mm(3)

- 32.0 mm(5)

- 35.0 mm(1)

- 38.1 mm(2)

- 40.0 mm(2)

- 42.0 mm(2)

- 50.0 mm(2)

- 50.8 mm(2)

- 52.0 mm(1)

- 63.0 mm(1)

komu

Maximum Cutting Diameter

Maximum Cutting Diameter

- 0.9843 in(4)

- 1.0 in(3)

- 1.25 in(3)

- 1.2598 in(5)

- 1.378 in(1)

- 1.5 in(2)

- 1.5748 in(2)

- 1.6535 in(2)

- 1.9685 in(2)

- 2.0 in(2)

- 2.0472 in(1)

- 2.4803 in(1)

komu

Cutting Length

Cutting Length

- 0.059 in(4)

- 0.0591 in(24)

komu

Reach

Reach

- 1.2598 in(3)

- 1.2599 in(2)

- 1.378 in(1)

- 1.5748 in(12)

- 1.5749 in(1)

- 1.6929 in(4)

- 1.9685 in(3)

- 2.0 in(1)

- 2.7559 in(1)

komu

Reach

Reach

- 32.0 mm(5)

- 35.0 mm(1)

- 40.0 mm(13)

- 43.0 mm(4)

- 50.0 mm(3)

- 50.8 mm(1)

- 70.0 mm(1)

komu

Connection Style

Connection Style

- A-Socket Head Cap Screw (11)

- Screw-On Connection (5)

- Straight-Cylindrical (7)

- Weldon (5)

Number of Flutes

Number of Flutes

- 2 (2)

- 3 (9)

- 4 (7)

- 5 (6)

- 6 (3)

- 7 (1)

Over All Length [L]

Over All Length [L]

- 1.2598 in(3)

- 1.2599 in(2)

- 1.5748 in(6)

- 2.2441 in(1)

- 2.6575 in(4)

- 3.7795 in(2)

- 3.856 in(3)

- 7.874 in(5)

- 8.0 in(1)

- 9.8425 in(1)

komu

Over All Length [L]

Over All Length [L]

- 32.0 mm(5)

- 40.0 mm(6)

- 57.0 mm(1)

- 67.5 mm(4)

- 96.0 mm(2)

- 97.943 mm(3)

- 200.0 mm(5)

- 203.2 mm(1)

- 250.0 mm(1)

komu

application

Grade Of Cutting Tool

Grade Of Cutting Tool

- WP25PM (28)

- WP40PM (28)

- WS40PM (28)

Maximum Ramp Angle

Maximum Ramp Angle

- 0.5 (1)

- 0.7 (5)

- 0.8 (3)

- 1.0 (1)

- 1.1 (2)

- 1.33 (1)

- 1.5 (8)

- 2.7 (3)

- 2.8 (4)

komu

frontEnd

Neck Diameter

Neck Diameter

- 0.8425 in(5)

- 0.8504 in(1)

- 1.1181 in(4)

- 1.1796 in(1)

- 1.1914 in(1)

komu

Neck Diameter

Neck Diameter

- 21.4 mm(5)

- 21.6 mm(1)

- 28.4 mm(4)

- 29.961 mm(1)

- 30.261 mm(1)

komu

backEnd

Connection Type

Connection Type

- CYLINDRICAL (12)

- SCREW-ON (5)

- SHELL MILL (11)

Back-End Diameter

Back-End Diameter

- 12.7 mm(2)

- 16.0 mm(3)

- 19.05 mm(2)

- 21.0 mm(1)

- 22.0 mm(4)

- 25.0 mm(6)

- 25.4 mm(5)

- 29.0 mm(4)

- 31.75 mm(1)

komu

Back-End Diameter

Back-End Diameter

- 0.5 in(2)

- 0.6299 in(3)

- 0.75 in(2)

- 0.8268 in(1)

- 0.8661 in(4)

- 0.9843 in(6)

- 1.0 in(5)

- 1.1417 in(4)

- 1.25 in(1)

komu

No filters matching ""