Produkt podobný k:

TCAX • 1103..

Břitové destičky M94 • 1103..

Objednací číslo2026017

ISO katalogové IDTCAX1103ZZ21ASI katalogové IDTCAX1103ZZ21

- K Cast Iron

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 2026017 |

| ISO katalogové ID | TCAX1103ZZ21 |

| ASI katalogové ID | TCAX1103ZZ21 |

| Grade | THM |

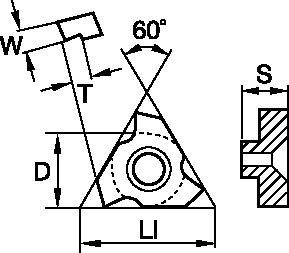

| [D] Insert IC Size | 6.35 mm |

| [D] Insert IC Size | 0.25 in |

| [LI] Insert Length | 11 mm |

| [LI] Insert Length | 0.4331 in |

| [W] Cutting Width | 2.23 mm |

| [W] Cutting Width | 0.0878 in |

| [T] Cuttg Depth | 2.25 mm |

| [T] Cutting Depth | 0.0886 in |

| [S] Insert Thickness | 3.2 mm |

| [S] Insert Thickness | 0.126 in |

| Average Chip Thickness [HM] | 0.07 mm |

| Average Chip Thickness [HM] | 0.0028 in |

Materiály obrobků

- Cast Iron

- Non-Ferrous

Karbidy

THM

Uncoated carbide. Extraordinarily good balance of hardness, wear resistance, edge stability, and toughness. Light and medium machining. For cast iron and all non-ferrous metals and non-metals. Useful in unfavorable conditions.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Posuvy

Recommended Starting Feeds [mm]

| Geometrie břitových destiček | Programovaný posuv na zub (fz) jako % poměr radiální hloubky řezu (ae) | Geometrie břitových destiček | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| TCAX/TNAX | 0,12 | 0,29 | 0,45 | 0,08 | 0,21 | 0,33 | 0,06 | 0,16 | 0,25 | 0,06 | 0,14 | 0,21 | 0,05 | 0,13 | 0,20 | TCAX/TNAX |

| Lehké obrábění | Všeobecné použití | Těžké obrábění |

Rychlosti

Recommended Starting Speeds [m/min]

| Materiálová skupina | THM | TTM/TTM08 | |||||

| P | 1 | – | – | – | 560 | 490 | 460 |

| 2 | – | – | – | 345 | 280 | 245 | |

| 3 | – | – | – | 345 | 280 | 245 | |

| 4 | – | – | – | 280 | 195 | 180 | |

| 5 | – | – | – | 360 | 280 | 260 | |

| 6 | – | – | – | 165 | 130 | 115 | |

| M | 1 | – | – | – | 330 | 195 | 130 |

| 2 | – | – | – | 195 | 115 | 80 | |

| 3 | – | – | – | 215 | 130 | 100 | |

| K | 1 | 395 | 295 | 245 | – | – | – |

| 2 | 410 | 330 | 230 | – | – | – | |

| 3 | 425 | 310 | 195 | – | – | – | |

| N | 1 | 2950 | 1970 | 1640 | – | – | – |

| 2 | 2245 | 1525 | 1265 | – | – | – | |

| 3 | 1475 | 920 | 655 | – | – | – | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

Výběr břitové destičky

Insert Selection Guide

| Materiálová skupina | Lehké obrábění | Všeobecné použití | Těžké obrábění | |||

| Geometrie | Sorta | Geometrie | Sorta | Geometrie | Sorta | |

| P1–P2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| P3–P4 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| P5–P6 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| M1–M2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| M3 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| K1–K2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| K3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| N1–N2 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| N3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S1–S2 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S4 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data