Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Logout

Item(s) successfully added to cart

View Cart

View Cart

Buy More Inserts, Save More on Steel Shop Now

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Solid End Milling

- /

- High-Performance End Mills

- /

- Roughers

- /

- Roughers • Series 4U70 • Radius • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

Roughers • Series 4U70 • Radius • Metric

Series 4U70 • Metric

Features and benefits

- Centre cutting.

- Flat shallow pitch.

- Unequal flute spacing.

- Standard items listed. Additional styles and coatings made-to-order.

Uses and application

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

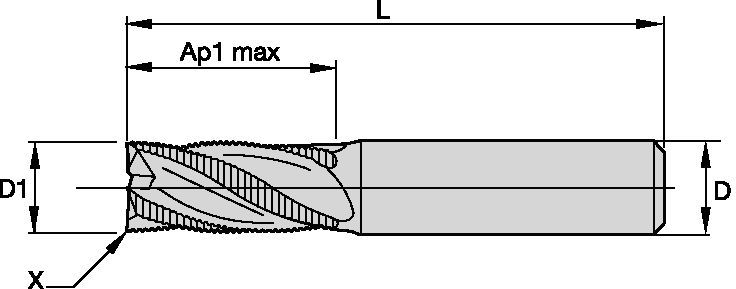

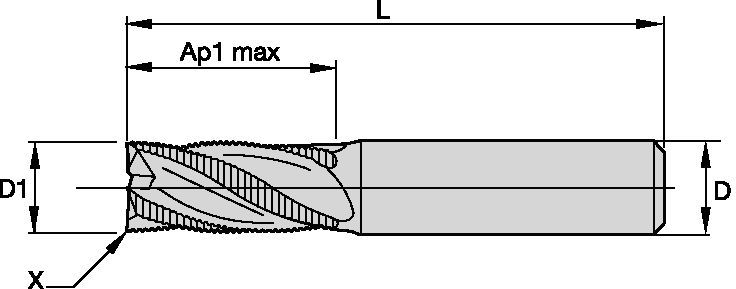

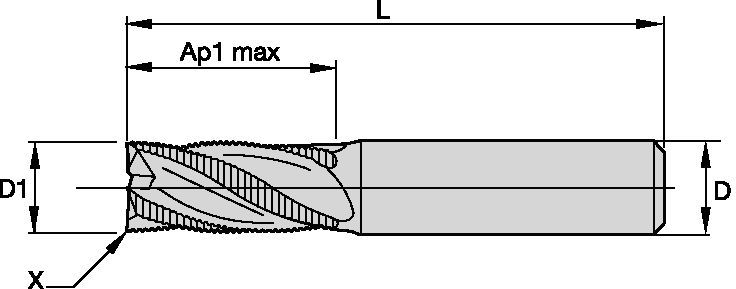

Tool Dimensions: Flute Configuration: X (variable)

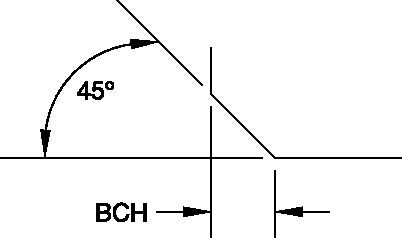

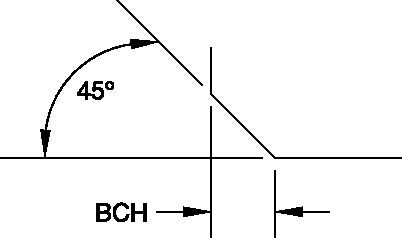

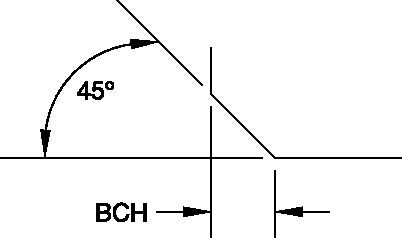

Corner Style: Corner Chamfer

Shank - Cylindrical Plain

Shank - Cylindrical Weldon

Helix Angle: 45°

Application Data • Series 4U70 • Metric

|  |  | |||||||||||||

| Side Milling (A) and Slotting (B) | WP15PE | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||

| A | B | Cutting Speed | D1 | ||||||||||||

| Material | ap | ae | ap | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 3 | 1 x D | 0,5 x D | 0,75 x D | 120 | – | 160 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 4 | 1 x D | 0,3 x D | 0,75 x D | 90 | – | 150 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 | |

| 5 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 100 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 6 | 1 x D | 0,3 x D | 0,3 x D | 50 | – | 75 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| M | 1 | 1 x D | 0,5 x D | 0,75 x D | 90 | – | 115 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 80 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 3 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 70 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| K | 1 | 1 x D | 0,5 x D | 1 x D | 120 | – | 150 | fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 2 | 1 x D | 0,5 x D | 1 x D | 110 | – | 140 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 3 | 1 x D | 0,5 x D | 1 x D | 110 | – | 130 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| S | 1 | 1 x D | 0,3 x D | 0,75 x D | 50 | – | 90 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 3 | 1 x D | 0,4 x D | 0,75 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 4 | 1 x D | 0,4 x D | 0,75 x D | 50 | – | 60 | fz | 0,026 | 0,037 | 0,045 | 0,052 | 0,064 | 0,074 | 0,084 | |

| H | 1 | 1 x D | 0,3 x D | 0,3 x D | 80 | – | 140 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 |

| 2 | 1 x D | 0,2 x D | 0,2 x D | 70 | – | 120 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| 3 | 1 x D | 0,2 x D | 0,2 x D | 60 | – | 90 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |