Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Buy More Inserts, Save More on Steel

Shop Now

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- VSM890™-12 • SNHX-MM • Universal Geometry for Medium Machining

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

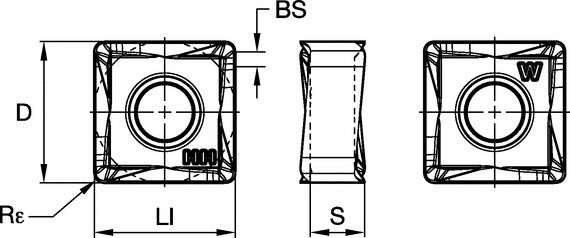

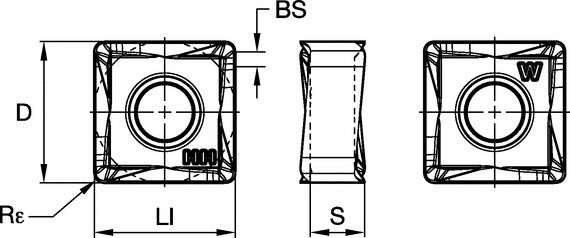

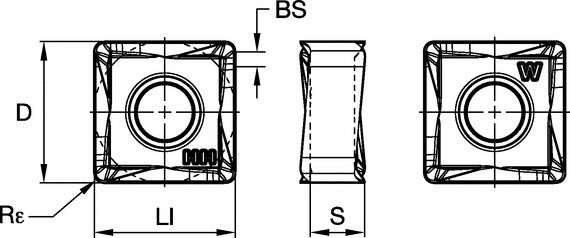

VSM890™-12 • SNHX-MM • Universal Geometry for Medium Machining

Inserts • SNHX-MM • Universal Geometry for Medium Machining

Features and benefits

- -MM First choice for general purpose in all workpiece materials. Engineered for high feed rates.

- Unique insert rake design to reduce and perfectly balance axial and radial cutting forces.

- Engineered for light machining to heavy roughing in all material groups.

Insert Selection Guide

| Light

|

General

|

Heavy

|

||||

| Material

|

Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P3–P4 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P5–P6 | SNHX-ML | WP25PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| M1–M2 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| M3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| K1–K2 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| K3 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| N1–N2 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| N3 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| S1–S2 | SNHX-ML | WP25PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S4 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| H1 | SNHX-MM | WU10PM | SNHX-MM | WU10PM | – | – |

Recommended Starting Feeds [mm]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | 0,12 | 0,28 | 0,43 | 0,08 | 0,20 | 0,31 | 0,06 | 0,15 | 0,23 | 0,06 | 0,13 | 0,20 | 0,05 | 0,12 | 0,18 | .E..ALP |

| .E..ML | 0,17 | 0,32 | 0,60 | 0,13 | 0,23 | 0,44 | 0,09 | 0,18 | 0,33 | 0,08 | 0,15 | 0,28 | 0,08 | 0,14 | 0,26 | .E..ML |

| .S..MM | 0,23 | 0,36 | 0,82 | 0,17 | 0,26 | 0,59 | 0,13 | 0,20 | 0,44 | 0,11 | 0,17 | 0,38 | 0,10 | 0,16 | 0,35 | .S..MM |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | .005 | .010 | .015 | .003 | .007 | .011 | .003 | .005 | .008 | .002 | .005 | .007 | .002 | .004 | .006 | .E..ALP |

| .E..ML | .007 | .012 | .023 | .005 | .009 | .017 | .004 | .007 | .012 | .003 | .006 | .011 | .003 | .005 | .010 | .E..ML |

| .S..MM | .009 | .014 | .032 | .007 | .010 | .023 | .005 | .008 | .017 | .004 | .007 | .015 | .004 | .006 | .014 | .S..MM |

| Light

|

General

|

Heavy

|

Recommended Starting Speeds [m/min]*

| Material Group | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | – | – | – | |

| 6 | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | – | – | – |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | – | – | – | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | – | – | – | |

| K | 1 | 420 | 385 | 340 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | 295 | 265 | 240 |

| 2 | 335 | 295 | 275 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | 230 | 205 | 190 | |

| 3 | 280 | 250 | 230 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | 195 | 175 | 160 | |

| N | 1 | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 130 | 90 |

Recommended Starting Speeds [SFM]*

| Material Group | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 1085 | 935 | 885 | 1490 | 1295 | 1210 | 970 | 855 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 900 | 785 | 655 | 915 | 835 | 750 | 820 | 705 | 590 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 750 | 670 | 755 | 640 | 525 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 740 | 605 | 490 | 620 | 570 | 520 | 675 | 560 | 445 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 605 | 560 | 490 | 850 | 750 | 685 | 560 | 510 | 445 | 560 | 475 | 395 | – | – | – | |

| 6 | – | – | – | – | – | – | 540 | 410 | 330 | 520 | 440 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 675 | 590 | 540 | 670 | 605 | 505 | 640 | 560 | 510 | 690 | 560 | 460 | – | – | – |

| 2 | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 520 | 455 | 575 | 490 | 410 | 590 | 475 | 395 | – | – | – | |

| 3 | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | – | – | – | |

| K | 1 | 1380 | 1265 | 1115 | – | – | – | 755 | 675 | 605 | 965 | 865 | 785 | – | – | – | – | – | – | 970 | 870 | 785 |

| 2 | 1100 | 970 | 900 | – | – | – | 590 | 525 | 490 | 770 | 685 | 620 | – | – | – | – | – | – | 755 | 675 | 625 | |

| 3 | 920 | 820 | 755 | – | – | – | 490 | 445 | 395 | 635 | 570 | 520 | – | – | – | – | – | – | 640 | 575 | 525 | |

| N | 1 | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | – | – | – | |

| 4 | – | – | – | – | – | – | 230 | 165 | 115 | 215 | 160 | 105 | 215 | 165 | 115 | 195 | 165 | 100 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 525 | 425 | 295 |