Product Similar To:

CCMT-MU • Medium Universal

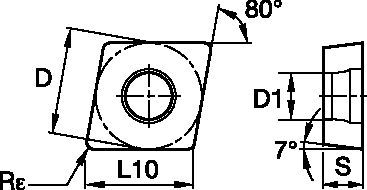

CCMT-MU

Material Number5623423

ISO Catalog IDCCMT090308MUANSI Catalog IDCCMT322MU

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5623423 |

| ISO Catalog ID | CCMT090308MU |

| ANSI Catalog ID | CCMT322MU |

| Grade | WM25CT |

| [D] Insert IC Size | 9.525 mm |

| [D] Insert IC Size | .375 in |

| [L10] Insert Cutting Edge Length | 9.672 mm |

| [L10] Insert Cutting Edge Length | .3808 in |

| [S] Insert Thickness | 3.18 mm |

| [S] Insert Thickness | .1252 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | .0315 in |

| [D1] Insert Hole Size | 4.4 mm |

| [D1] Insert Hole Size | .1732 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use