Cenově dostupný výkon

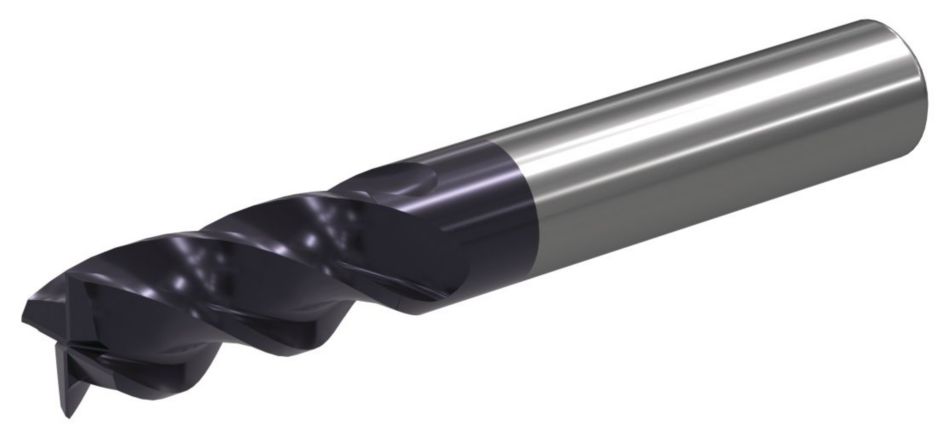

Platforma čelních stopkových fréz WCE představuje spojení vysoce výkonných a univerzálních funkcí v jedné řadě čelních stopkových fréz. Nabízíme je za dostupnou cenu v geometriích se 4 nebo 5 břity. Tato fréza je vhodná do malých až středně velkých dílen a je určená pro malosériové obrábění.

Geometrie frézy WCE4 se 4 břity za dostupnou cenu kombinuje asymetrické umístění břitů a šroubovici s proměnným stoupáním. To umožňuje frézování různých materiálů i využití pro náročné úkony, jako je frézování drážek do plného materiálu nebo frézování s velkou hloubkou řezu.

Geometrie WCE5 s 5 břity kombinuje vlastnosti nerovnoměrného dělení břitů se zvýšenou, 38stupňovou šroubovicí za dostupnou cenu. Hodí se především na rohové a boční frézování uhlíkové a nerezové oceli.