Product Similar To:

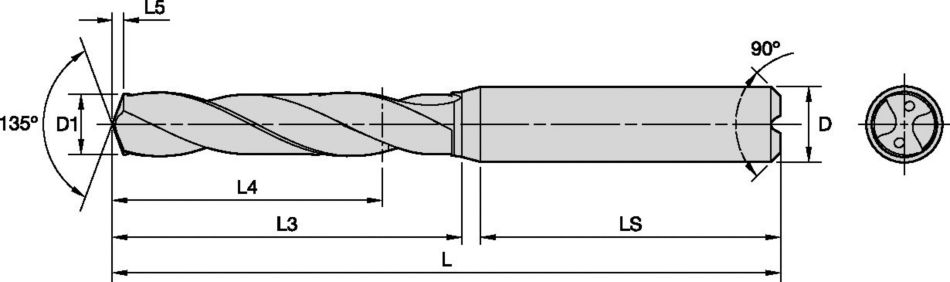

TDS422A • WN15HD™ • A-Shank • 5 x D

TOP DRILL S™ with Through Coolant • Non Ferrous Materials

Material Number6288611

ISO Catalog IDTDS422A14000ANSI Catalog IDTDS422A14000

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

38513

38563

DIN Numbers: ER Collet

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6288611 |

| ISO Catalog ID | TDS422A14000 |

| ANSI Catalog ID | TDS422A14000 |

| Grade | WN15HD |

| [D1] Drill Diameter M | 14 mm |

| [D1] Drill Diameter M | .5512 in |

| [L] Overall Length | 124 mm |

| [L] Overall Length | 4.881 in |

| [L3] Flute Length | 77 mm |

| [L3] Flute Length | 3.031 in |

| [L4] Maximum Drilling Depth | 60 mm |

| [L4] Maximum Drilling Depth | 2.362 in |

| [L5] Drill Point Length | 2.414 mm |

| [L5] Drill Point Length | .095 in |

| [LS] Shank Length | 45 mm |

| [LS] Shank Length | 1.771 in |

| [D] Adapter / Shank / Bore Diameter | 14 mm |

| [D] Adapter / Shank / Bore Diameter | .5512 in |

Uses and application

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

38513

38563

DIN Numbers: ER Collet

Features and benefits

- Top Drill S™ for Aluminum machining.

- High polished flutes for to ensure a perfect chip evacuation and prevenet from built-up-edge, even machining with MQL.

- Sharp cutting edges for a perfect cutting action on Aluminum and the others non-ferrous materials.

- Wide flutes to guarantee a perfect chip flow even at high feedrates.

- Shank accorgin to DIN 69090-3 (round cylindrical for MQL).

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use